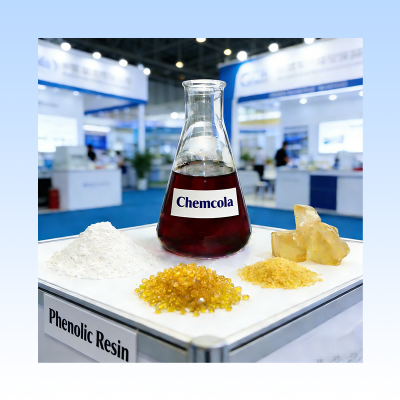

Friction Material Phenolic Resins

Product Name: Friction Material Phenolic Resins

Primary Uses: Brake Pads, Clutch Facings, Industrial Applications

Product Grades: General-Grade and Enhanced High-Performance Resins

Core Advantages: Real-World Braking Performance, Process Adaptability

Product Form: Powder or Flake for Easy Production Integration

Environmental Features: Supports Asbestos-Free and Eco-Friendly Formulations

Quality Assurance: Certified Manufacturing with Consistent Quality Control

Customer Support: Tailored Packaging, Logistics, SGS Reports on Request

Choosing the right phenolic resin can define the performance and safety of your friction materials. We specialize in supplying resins tailored for brake pads, clutch facings, and industrial friction products used in a wide range of vehicles and machinery.

Our product lineup includes:

General-Grade Resins

Suited for cost-sensitive applications without sacrificing core performance. These resins offer good friction characteristics and processing flexibility.Enhanced High-Performance Resins

Designed for demanding operating conditions—such as frequent high-load braking or elevated temperature environments. These resins provide superior thermal stability, consistent friction, and options for rubber or epoxy modification.

Why Partner With Us?

Resins engineered for real-world braking and clutch performance

Grades available to support asbestos-free and eco-friendly formulations

Controlled curing and flow properties to simplify production

Powder and flake formats for easy integration into your process

Backed by certified manufacturing and quality assurance systems

We offer tailored packaging, responsive logistics, and the option to obtain SGS test reports to meet your compliance and quality verification needs.

Let’s identify the best resin for your next project. Share your requirements, and we’ll provide detailed technical information and working samples.