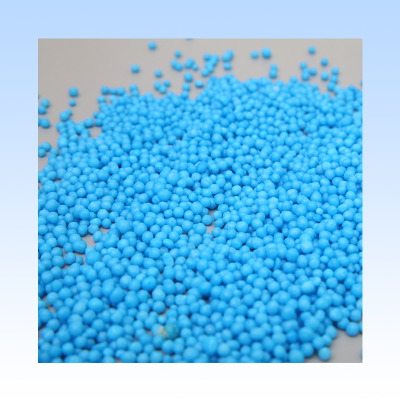

Urea Molding Compound (UMC)

Product Name: Urea Molding Compound (UMC)

Type: Thermoset molding compound powder

Base Material: Premium urea-formaldehyde resin powder

Form: Free-flowing thermosetting powder

Applications: Multiple industrial uses

Urea Molding Compound (UMC) – Your Trusted Thermosetting Material

Looking for reliable urea moulding compound? Our Urea Formaldehyde Moulding Compound delivers consistent performance. This thermosetting material is perfect for various industrial applications.

What We Offer:

High-quality Urea Molding Compound (UMC)

Stable urea formaldehyde moulding compound

Customized urea moulding compound solutions

Competitive UMC pricing

Product Advantages:

Our UMC stands out for its excellent electrical properties. It offers good heat resistance and mechanical strength. The material maintains color stability over time. You get consistent results with every batch.

Technical Features:

Material Type: Urea Formaldehyde Moulding Compound

Form: Free-flowing powder

Color Options: Multiple choices available

Processing Methods: Compression and transfer molding

Storage Requirements: Cool, dry conditions recommended

Common Applications:

Manufacturers choose our urea moulding compound for:

Electrical components and switches

Household appliances parts

Decorative hardware items

Kitchenware and utensils

Industrial equipment components

Quality Commitment:

We test every batch of UMC thoroughly. Our quality control team ensures product consistency. Technical specifications are verified before shipment. You receive exactly what you ordered.

Service Benefits:

Direct factory UMC pricing

Flexible order quantities

Custom formulation options

Professional technical support

Reliable delivery schedules

Packaging Choices:

Standard 25kg bags

Custom packaging solutions

Bulk container options

Palletized shipments

Inside Our Operation - What This Means for You

The manufacturing facilities we work with maintain 1,500 tons of raw material inventory across three warehouses. Having walked these facilities last month, I can confirm their new drying system has reduced moisture variation between batches by 18%. This translates to more predictable processing in your operations.

How We Support Your Success - Beyond the Invoice

Our technical team provides comprehensive support, including:

Processing parameter optimization - We'll work with your production team to establish ideal settings

Troubleshooting assistance - Available through WhatsApp for urgent production issues

Sample matching service - Turnaround typically 3-5 working days for color matching

Documentation and Quality Assurance - What You'll Receive

Each shipment includes:

Batch-specific Certificate of Analysis with actual test values

Updated Material Safety Data Sheet (MSDS section 3 specifies 68% urea formaldehyde resin)

Third-party inspection reports available before shipment when the order quantity exceeds 100 tons.

Shipping documents with container and seal numbers for tracking

Global Logistics - How Your Order Moves

Recent shipping experiences:

Vietnam orders: 22 days average from order to arrival

Mexican shipments: 18 days with complete customs documentation

Brazilian imports: 25 days including all certification requirements

Common Questions We Address - Direct from Our Inbox

"What's your response time for technical issues?"

Typically under 4 hours during business hours, with emergency contacts for production-critical situations.

"Do you keep records of our preferred processing parameters?"

Yes, we maintain a client-specific database to ensure consistency across repeat orders.

"Can you accommodate rush orders for urgent production needs?"

Our inventory system allows for 3-day expedited processing for established partners.

Industry Presence and Client Validation

We regularly participate in international plastics exhibitions, including recent events in Guangzhou and Bangkok. These engagements consistently reveal new application opportunities and allow for direct technical exchange.

Next Steps for Collaboration

I recommend beginning with a production trial of 500kg to evaluate material performance in your specific application. This quantity typically supports 2-7days of production testing while maintaining cost efficiency.

For detailed pricing and to discuss your specific requirements, please contact me directly with your application details and monthly consumption estimates. I'll ensure you receive comprehensive technical support and commercial terms aligned with your operational needs.